Type 1 Adjustable steel clevis hanger (figure 9)

A pipe attachment for suspension of horizontal stationary lines and providing a means for vertical adjustment.

Type 2 Yoke-type pipe clamp

A pipe attachment for suspension of horizontal stationary insulated lines. This type of clamp is also made to accommodate pipe of nonstandard size when designed with a filler plate.

Type 3 Carbon- or alloy-steel three-bolt pipe clamp

A pipe attachment for suspension of horizontal stationary lines.

Type 4 Steel pipe clamp

A pipe attachment for suspension of horizontal stationary insulated lines.

Type 5 Pipe hanger

A pipe attachment for suspension of horizontal stationary lines either using a hanger rod or bolting to wall from the T slot provided in the side of the strap.

Type 6 Adjustable swivel pipe, split ring type or solid ring type

A pipe attachment for suspension of horizontal stationary lines.

Type 7 Adjustable steel band hanger

A pipe attachment for suspension of horizontal stationary lines and providing a means for vertical adjustment.

Type 8 Extension pipe or riser clamp

A pipe attachment for suspension of vertcal stationary lines without the use of hanger rods. The transfer of piping load is accomplished by resting the ears of the clamp on a bearing surface.

Type 9 Adjustable band hanger

A pipe attachment for suspension of horizontal stationary lines.

Type 10 Adjustable swivel ring, band type

A pipe attachment for suspension of horizontal stationary lines and providing a means for vertical adjustment.

Type 11 Split pipe ring with or without turnbuckle adjustment

A pipe attachment for suspension of horizontal stationary lines permitting installation before or after pipe is in place.

Type 12 Extension split pipe clamp, hinged or two-bolt

A pipe attachment for suspension of horizontal stationary lines used in conjunction with a pipe nipple.

Type 13 Steel turnbuckle

A device with one left-hand internal threaded end and one right-hand internal threaded end, used to join two threaded rods and providing for vertical adjustment.

Type 14 Steel clevis

A device which provides for the attachment of a threaded rod to a bolted or pinned connection.

Type 15 Swivel turnbuckle

A device which provides flexibility at the pipe connection and a means of vertical adjustment.

Type 16 Malleable iron socket

A device for attaching threaded rods to various types of building attachments.

Type 17 Steel weldless eye nut

A forged-steel device which provides for the attachment of a threaded rod to a bolt or pin connection.

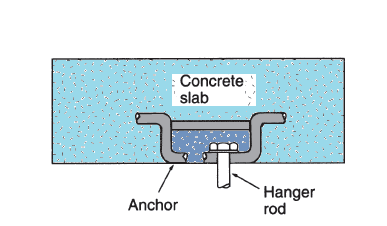

Type 18 Steel or malleable concrete insert

A cast-in-place device which provides for a rod attachment capable of nominal lateral adjustment.

Type 19 Top beam C-clamp

A device requiring no welding which attaches to the top flange of a structural shape where the vertical rod is required to be offset from the edge of the flange.

Type 20 Side beam or channel clamp

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be at the edge of the flange.

Type 21 Center beam

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be centered on the structural shape.

Type 22 Welded beam attachment (as shown or inverted less bolt)

A structural attachment welded to the bottom of steel beams and used as a means for connecting hanger rods to the beams.

Type 23 C-clamp

A device requiring no welding which attaches to a flange of a structural shape and provides for attaching a threaded rod.

Type 24 U-bolt

A U-shaped rod with threaded ends used as a support or guide.

Type 25 Top beam clamp

A device requiring no welding which attaches to the top flange of a structural shape where the vertical rod is required to be at the edge of the flange.

Type 26 Pipe clip

A pipe attachment for suspension of horizontal stationary lines by bolting the clip directly to a structure. Also referred to as a pipe strap or strap.

Type 27 Side beam clamp

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be offset from the center of the shape.

Type 28 Steel beam clamp with eye nut

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be centered on the structural shape.

Type 29 Linked steel clamp with eye nut

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be centered on the structural shape.

Type 30 Malleable beam clamp with extension piece

A device requiring no welding which attaches to the bottom flange of a structural shape where the vertical rod is required to be centered on the structural shape.

Type 31 Light welded steel bracket

A braced cantilever device intended for supporting a gravity load from rod-type hangers. This device is typically bolted to a wall and may be installed with the brace either above or below the horizontal member.

Type 32 Medium welded steel bracket

A braced cantilever device intended for supporting maximum gravity loads and/or horizontal loads up to 1500 lb (6670 newton, N). Loads may be applied anywhere along the main member. This device is typically bolted to a wall and may be installed with the brace above, below, or on either side of the main member.

Type 33 Heavy welded steel bracket

A braced cantilever device intended for supporting maximum gravity loads and/or horizontal loads up to 3000 lb (13,340 newton, N). Loads may be applied anywhere along the main member. This device is typically bolted to a wall and may be installed with the brace above, below, or on either side of the main member.

Type 34 Side beam bracket

A device requiring no welding which attaches to the sides of steel or wooden members and provides a means for vertical adjustment.

Type 35 Pipe slide and slide plate

A device for supporting piping having horizontal movements and where a low coefficient of friction is necessary.

Type 36 Pipe saddle support

A device having a curved base for cradling horizontal pipe and which slips into a nominal diameter pipe stanchion.

Type 37 Pipe stanchion saddle

A device having a curved base for cradling horizontal pipe and which slips into a nominal diameter pipe stanchion. The U-bolt yoke provides stability.

|

| FIG 9 |

Type 38 Adjustable pipe saddle support

A device having a curved base for cradling horizontal pipe and which threads into a nominal diameter pipe stanchion. This device provides vertical adjustment.

Type 39 Steel pipe-covering protection saddle

A device used on insulated piping which is designed to minimize heat losses and prevent damage to insulation.

Type 40 Protection saddle

A metal device intended to prevent crushing of insulation and/or breaching of the vapor barrier. It is typically used at support points.

Type 41 Single pipe roll

A device used for supporting horizontal piping from two rods, allowing for vertical adjustment and consisting of a roller that allows for axial movement with virtually no frictional resistance.

Type 42 Carbon- or alloy-steel riser clamp

A pipe attachment for supporting vertical piping through the use of shear lugs welded to the pipe. Load bolts are provided to transfer the pipe load to the rod hanger assembly.

Type 43 Adjustable roller hanger with or without swivel

A device used for supporting horizontal piping from a single rod, allowing for vertical adjustment and consisting of a roller that allows for axial movement with virtually no frictional resistance.

Type 44 Pipe roll complete

A device used for supporting horizontal piping where vertical adjustment is unnecessary and consisting of a roller that allows for axial movement with virtually no frictional resistance.

Type 45 Pipe roll and plate

A device used to support horizontal piping, having minimal axial movement, from beneath and where no vertical adjustment is necessary.

Type 46 Adjustable pipe roll and base

A device used to support horizontal piping, having axial movement, from beneath and where vertical adjustment is necessary.

Type 47 Restraint control device

A rigid, mechanical, spring, or hydraulic device used for absorbing shock loading and/or controlling sway in piping systems.

Type 48 Spring cushion

A noncalibrated, rod-type, single-coil spring support used where a cushioning effect is desired.

Type 49 Spring cushion roll

A non-calibrated, rod-type, double-coil rod spring support used where a cushioning effect is desired along with a pipe roll.

Type 50 Spring sway brace

A spring device used for absorbing shock loading and/or controlling sway in piping systems.

Type 51 Variable spring hanger

A device having a single-spring coil which supports the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a varying load when the piping moves from the cold position to the hot position. This type of spring hanger supports the pipe from above.

Type 52 Variable spring base support

A device having a single-spring coil which supports the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a varying load when the piping moves from the cold to the hot position. This type of spring hanger supports the pipe from below.

Type 53 Variable spring trapeze hanger

A device having double-spring coils which support the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a varying load when the piping moves from the cold position to its hot position. This type of spring hanger supports the pipe from above with two rods.

Type 54 Constant support hanger, horizontal type

A device having a single-spring coil working in conjunction with counter balancing mechanisms to support the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a constant load when the piping moves from the cold position to the hot position. This type of constant hanger has the spring coil in the horizontal position and supports the pipe from above.

Type 55 Constant support hanger, vertical type

A device having a single-spring coil working in conjunction with counter balancing mechanisms to support the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a constant load when the piping moves from the cold position to the hot position. This type of constant hanger has the spring coil in the vertical position and supports the pipe from above.

Type 56 Constant support hanger, trapeze type

A device having double-spring coils working in conjunction with counter balancing mechanisms to support the gravity loads of piping systems that are subjected to vertical thermal movements. This device produces a constant load when the piping moves from the cold position to the hot position. This type of constant hanger has the spring coil in the vertical position and supports the pipe from below with two rods.

Type 57 Plate lug

A structural attachment which provides a means of connecting rod type hangers to structural steel members via a pin or bolt through the hole of the lug.

Type 58 Horizontal traveler

A device which permits the structural attachment end of rod-type hangers to accommodate horizontal piping movements in conditions where offsetting of conventional structural attachments is not practical due to limited space.

|

| FIG 10 |

Classification of Pipe Supports Based on Details, Constructions and Functions

Classification of Pipe Supports Broadly the pipe supports are classified in three groups as per following details / functions:

– General details

– Construction details

– Functions ie. Purpose

1. Pipe Supports Classification as per General Details:

A pipe line needs to be supported from a foundation or a structure. The piping loads will be acting on these foundations / structures. Since these foundations / structures are built on ground, they will exert an equal and opposite reaction, while supporting the pipe.

In a pipe support, there will be some parts of support arrangement which is directly attached to the pipeline and there will be some other parts which shall be directly attached to the foundation / structure supporting the pipe.

As per this general detail the support is classified as:

1.1 Primary Supports:

It is the parts of support assembly which is directly connected to the pipe.

1.2 Secondary Supports:

It is the parts of support assembly which is directly connected to the foundation / structure and is supporting the primary support attached to the pipe line.

2. Pipe Supports Classification as per Construction:

Based on construction details, pipe supports are broadly classified in three types, as

– RIGID SUPPORTS

– ELASTIC SUPPORTS

– ADJUSTABLE SUPPORTS

Pipe supports are fabricated from a variety of materials including structural steel, carbon steel, stainless steel, galvanized steel, aluminum, ductile iron and FRP composites. Most pipe supports are coated to protect against moisture and corrosion. Some methods for corrosion protection include: painting, zinc coatings, hot dip galvanizing or a combination of these. In the case of FRP composite pipe supports, the elements required to form a corrosion cell aren't present, so no additional coatings or protections are necessary

PIPE HANGER SIZING

Considerations for Designs the pipe supports with a minimum of effort :

- Operating Load or Installed Load

- Pipe Displacement at the Pipe Support

- Installed Height (Support) or Length (Hanger)

- Pipe Diameter

- Temperature of the Pipe

- Pipe Support Assembly or Sequence of Components Desired