Shear modulus or Modulus of rigidityوShear modulus or Modulus of rigidityوShear modulus or Modulus of rigidity

Engineering fastenings such as rivets, bolts, the different kinds of machine screws and setscrews, self-tapping screws and hinge pins are frequently subjected to shear loading. Shear loading occurs when equal and opposite parallel forces act on a component

Direct loading tends to cause failure perpendicular to the direction of loading whereas shear loading tends to cause failure parallel to the direction of loading

Shear stress

Shear stress : is a measure of the intensity of loading over the sheared area A.

shear strain = displacement of sheared surfaces/distance between sheared surfaces

Shear modulus or (Modulus of rigidity)

When an elastic material is subjected to shear loading, the displacement x of the sheared surfaces is proportional to the load F, which is applied. Also the shear stress 𝜏 is proportional to the

shear strain 𝛾

A graph of shear stress against shear strain is a straight line

‘stiffness’ of the material in shear and is known as its Shear Modulus, G. or Modulus of Rigidity

from (1) and (2)

Shear modulus is a measure of the shear stiffness of a material, i.e. its resistance to being deformed by shearing forces

It will be noted that several of the above formulae are similar to those derived for direct stress and strain and the Modulus of Elasticity but they should not be confused. The symbols F, A, l and x have different meanings when used to calculate shear stress, shear strain and shear modulus. Furthermore, the values of Modulus of Elasticity E, and Shear Modulus G, are not the same for any given material. With mild steel, for example, E=210 GNm⁻² whilst G= 85GNm⁻²

https://www.facebook.com/pro.mechanical.engineer/

Shear modulus or Modulus of rigidity

Engineering fastenings such as rivets, bolts, the different kinds of machine screws and setscrews, self-tapping screws and hinge pins are frequently subjected to shear loading. Shear loading occurs when equal and opposite parallel forces act on a component

Direct loading tends to cause failure perpendicular to the direction of loading whereas shear loading tends to cause failure parallel to the direction of loading

Shear stress

Shear stress : is a measure of the intensity of loading over the sheared area A.

shear stress = shear force /sheared area

𝜏 = F/A (Pa or Nm⁻²) (1)

Shear strain

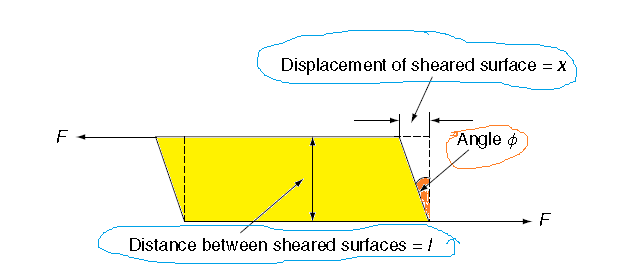

Shearing forces tend to distort the shape of a component as shown

Shear strain 𝛾, is a measure of the deformation which the shearing force produces. It is the ratio of the displacement of the sheared surfaces to the distance between them.shear strain = displacement of sheared surfaces/distance between sheared surfaces

𝛾 = x/l (2)

The angle 𝜙, is called the angle of shear. Its tangent is equal to the shear strain.

tan 𝜙 = x/l

tan 𝜙 = 𝛾

Shear modulus or (Modulus of rigidity)

When an elastic material is subjected to shear loading, the displacement x of the sheared surfaces is proportional to the load F, which is applied. Also the shear stress 𝜏 is proportional to the

shear strain 𝛾

A graph of shear stress against shear strain is a straight line

‘stiffness’ of the material in shear and is known as its Shear Modulus, G. or Modulus of Rigidity

G = 𝜏 / 𝛾 (Pa or Nm⁻²) (3)

from (1) and (2)

G = (F/A) /( x/l)

G = (F/A) × (l/x)

Shear modulus is a measure of the shear stiffness of a material, i.e. its resistance to being deformed by shearing forces

It will be noted that several of the above formulae are similar to those derived for direct stress and strain and the Modulus of Elasticity but they should not be confused. The symbols F, A, l and x have different meanings when used to calculate shear stress, shear strain and shear modulus. Furthermore, the values of Modulus of Elasticity E, and Shear Modulus G, are not the same for any given material. With mild steel, for example, E=210 GNm⁻² whilst G= 85GNm⁻²

https://www.facebook.com/pro.mechanical.engineer/

No comments:

Post a Comment

thanks for your visit