Introduction To Wheel Bearings Types and Installation

Introduction To Wheel Bearings Types and Installation

Introduction

Many different types of bearings are used in the automobile. A bearing may be defined as a component that supports and guides one of these parts:

1. Pivot

2. Wheel

3. Rotating shaft

4. Oscillating shaft

5. Sliding shaft

While a bearing is supporting and guiding one of these components, the bearing is designed to reduce friction and support the load applied by the component and related assemblies. Since the bearing reduces friction, it also decreases the power required to rotate or move the component. Bearings are precision-machined assemblies, which provide smooth operation and long life. When bearings are properly installed and maintained, bearing failure is rare.

Bearing Loads

When a bearing load is applied in a vertical direction on a horizontal shaft, it is called a radial bearing load . If the vehicle weight is applied straight downward on a bearing, this weight

is a radial load on the bearing. A thrust bearing load is applied in a horizontal direction

(Figure 1). For example, while a vehicle is turning a corner, horizontal force is applied to the

front wheel bearings. When an angular bearing load is applied, the angle of the applied load is somewhere between the horizontal and vertical positions.

|

| FIG 1 |

Bearing Types

Ball Bearings

Front and rear wheel bearings may be ball bearings or roller bearings. Either type of bearing contains these basic parts:

1. Inner race, or cone

2. Rolling elements, balls, or rollers

3. Separator, also called a cage or retainer

4. Outer race, or cup

A single-row ball bearing has a crescent-shaped machined surface in the inner and outer races in which the balls are mounted (Figure 2). When a ball bearing is at rest, the load is distributed equally through the balls and races in the contact area. When one of the races and the balls begin to rotate, the bearing load causes the metal in the race to bulge out in front of the ball and flatten out behind the ball .this action creates a certain amount of friction within the bearing, and the same action is repeated for each ball while the bearing is rotating. If metal-to-metal contact is allowed between

the balls and the races, these components will experience very fast wear. therefore, bearing lubrication is extremely important to eliminate metal-to-metal contact in the bearing and reduce wear.

|

| FIG 2 |

Some rear axle bearings on rear-wheel drive cars are sealed on both sides and retained on the axle with a retainer ring figure 3

|

| FIG 3 |

In a tapered roller bearing , the inner and outer races are cone shaped. If imaginary lines extend through the inner and outer races, these lines taper and eventually meet at a point extended through the center of the bearing (Figure 4). the most important advantage of the tapered roller bearing compared to other bearings is an excellent capability to carry radial, thrust, and angular loads. In the tapered roller bearing, the rollers are mounted on cone-shaped precision surfaces in the outer and inner races. the bearing separator has an open space over each roller. Grooves cut in the side of the separator roller openings match the curvature of the roller. this design allows the rollers to rotate evenly without interference between the rollers and the separator. Lubrication and proper endplay

adjustment are critical on tapered roller bearings. A tapered roller bearing may be called a cup and cone.

|

| FIG 4 |

A needle roller bearing contains many small-diameter steel rollers in a thin outer race. this type of bearing is very compact, and it is used in steering gears where mounting space is limited. Most needle roller bearings do not have a separator, but the steel rollers push against each other and maintain the roller position. Rather than having an inner race, a machined surface on the mounting shaft contacts the inner surface of the rollers (Figure 5). the needle roller bearing is designed to carry radial loads; it does not withstand thrust loads.

|

| FIG 5 |

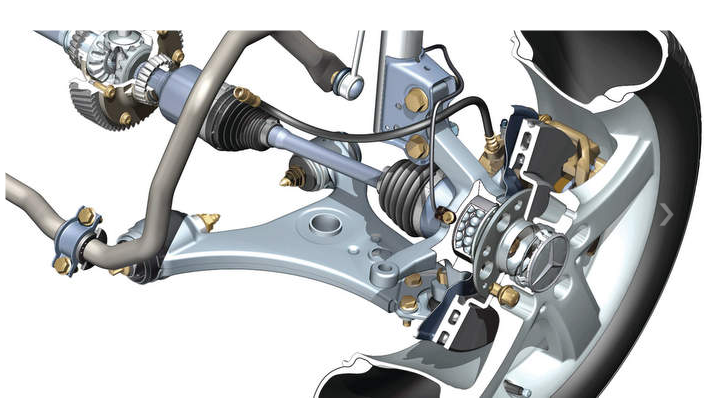

Some front-wheel-drive vehicles have front wheel bearing and hub assemblies that are bolted to the steering knuckles (Figure 6). the bearings are lubricated and sealed, and the complete bearing and hub assembly is replaced as a unit. the bearing hub unit is more compact than other types of wheel bearings mounted in the wheel hub. this type of bearing contains two rows of ball bearings with an angular contact angle of 32° . the inner bearing assembly bore is splined, and the inner ring extends to the outside to form a flange and spigot. the flange attached to the outer ring contains bolt holes, and bolts extend through these holes into the steering knuckle. this type of bearing attachment allows the bearing to become a structural member of the front suspension.

|

| FIG 6 |

Since the bearing outer ring is self-supporting, the main concern in knuckle design is fatigue strength rather than stifness. the drive axle shaft transmits torque to the inner bearing race. this shaft is not designed to hold the bearing together. this type of wheel bearing is designed for mid-sized front wheel-drive cars.

Each front drive axle has splines that fit into matching splines inside the bearing hubs (Figure7). A hub nut secures the drive axle into the inner bearing race. Some wheel bearing hubs contain a wheel speed sensor for the antilock brake system (ABS).

|

| FIG 7 |

Some front-wheel-drive vehicles have a sealed bearing unit that is pressed into the steering knuckle (Figure 8). the wheel hub is pressed into the inner bearing race, and the drive axle is splined into the hub. this type of bearing is designed for smaller front-wheel-drive cars. these bearings may contain two rows of ball bearings, or two tapered roller bearings and a split inner race (Figure 8). the bearing containing two tapered roller bearings has more radial load capacity than the double-row ball bearing. However, the tapered roller bearing is more sensitive to misalignment. Both sides of the bearing are sealed, and a seal is positioned behind the bearing in the steering knuckle to keep contaminants out of the bearing area.

|

| FIG 8 |

Other front-wheel-drive vehicles have two separate tapered roller bearings mounted in the steering knuckles.the bearing races are pressed into the steering knuckle, and seals are located in the knuckle on the outboard side of each bearing (Figure 9). Correct bearing endplay adjustment is supplied by the hub nut torque. the wheel hub is pressed into the inner bearing races, and the drive axle splines are meshed with matching splines in the wheel hub.

|

| FIG 9 |

Wheel Hubs with Two Separate Tapered Roller Bearings

Many rear-wheel-drive cars have two tapered roller bearings in the front hubs that support the hubs and wheels on the spindles. this type of front wheel bearing has the bearing races pressed into the hub. A grease seal is pressed into the inner end of the hub to prevent grease leaks and keep contaminants out of the bearings. the hub and bearing assemblies are retained on the spindle with a washer, adjusting nut, nut lock, and cotter pin. the adjusting nut must be adjusted properly to provide the correct bearing endplay. A grease cap is pressed into the outer end of the hub to prevent bearing contamination (Figure 10).

|

| FIG 10 |

|

| FIG 11 |

On many rear-wheel-drive cars, the rear axles are supported by roller bearings mounted near the outer ends of the axle housing. the outer bearing race is pressed into the housing, and a machined surface on the axle contacts the inner roller surface. A seal is mounted in the axle housing on the outboard side of each bearing (Figure 12). this type of axle bearing is usually not sealed, and lubricant in the differential and rear axle housing provides axle bearing lubrication. the seals prevent lubricant leaks from the outer ends of the axle housing and keep dirt out of the bearings.

Other rear-axle bearings on rear-wheel-drive vehicles have sealed roller bearings pressed onto the rear axles. these axle bearings are sealed on both sides, and an adapter ring is pressed onto the axle on the inboard side of the bearing (Figure 12). the outer bearing race is mounted in the rear axle housing with a light press fit and a seal is positioned in the housing on the inboard side of the bearing and adapter ring. A retainer plate is mounted between the bearing and the outer end of the axle. this retainer plate is bolted to the axle housing to retain the axle in the housing.

|

| FIG 12 |

⧪ A bearing reduces friction, carries a load, and guides certain components such as pivots, shafts, and wheels.

⧪ Radial bearing loads are applied in a vertical direction.

⧪ thrust bearing loads are applied in a horizontal direction.

⧪ Angular bearing loads are applied at an angle between the vertical and horizontal.

⧪ the inner bearing race is positioned at the center of the bearing and supports the rolling elements.

⧪ the rolling elements in a bearing are positioned between the inner and outer races.

⧪ the bearing separator keeps the rolling elements evenly spaced.

⧪ the outer bearing race forms the outer ring on a bearing.

⧪A cylindrical ball bearing is designed primarily to withstand radial loads, but these bearings can handle a considerable thrust load.

⧪ A snapring can be mounted in a groove in the outer bearing race, and the snapring retains the bearing in the housing.

⧪ A bearing shield prevents dirt from entering the bearing, but it is not designed to keep lubricant in the bearing.

⧪ Bearing seals keep lubricant in the bearing and prevent dirt from entering the bearing.

⧪ Roller bearings are designed primarily to carry radial loads, but they can handle some thrust loads.

⧪ Tapered roller bearings have excellent radial, thrust, and angular load-carrying capabilities.

⧪ Needle roller bearings are very compact and are designed to carry radial loads. they will not carry thrust loads.

⧪ Springless seals are used for wheel bearing seals in some wheel hubs.

⧪ the garter spring provides additional force on the seal lip to compensate for lip wear, shaft movement, and bore eccentricity.

⧪ Flutes on seal lips provide a pumping action to direct oil back into a housing.

⧪ Bearing hub units are compact compared to bearings that are mounted in the wheel hub. this compactness makes bearing hub units suitable for front-wheel-drive cars.

⧪ Some bearing hub units are bolted to the steering knuckle; other bearing hub units are pressed into the steering knuckle.

⧪ Some steering knuckles contain two separate tapered roller bearings.

⧪ Rear-axle bearings are mounted between the drive axles and the housing on rear-wheel-drive cars.

Labels: MECHANICAL ENGINEERING

1 Comments:

We are pleased to introduce ourselves as one of the leading suppliers of Bearings since 1990. Named Lakshmi Trading Company. We deal with a various range of products, such as SKF, FAG, ZKL & JAPAN and also Supplier of Plummer Blocks And Sleeves of Various Brands. We are Specialists in Needle Rollers in Delhi, Unit & Rail Guide Bearing in Delhi, Ball Screw With Net Various make like INA, IKO, HAWIN, ABBA, Etc.

Plain Bearing in Delhi

Jewel Bearing in Delhi

Fluid Bearing in Delhi

Flexure Bearing in Delhi

Post a Comment

thanks for your visit

Subscribe to Post Comments [Atom]

<< Home