Centrifugal Pumps Principles , Properties And Applications

Introduction

Pumps can be classified into two categories based on the method by which pumping energy is transmitted to the fluid: kinetic and positive displacement pumps. Most kinetic pumps are centrifugal pumps. Liquid flowing into the suction side or inlet of a centrifugal pump is captured by the impeller and thrown to the outside of the pump casing, or volute. The volute converts the velocity imparted to the fluid by the impeller into pressure.

Pump Types

Centrifugal pumps are divided into:

· Single and multistage volute types with single and double suction impellers.

· Multistage diffuser types with single suction impellers.

These are further divided into:

· Radial or vertical split or

· Axial or horizontal split case types.

Volute type pumps are further divided into:

· Single Volute

· Double volute

All casings of the radial or vertical split have the casing split at right angles to the shaft centerline, whereas, the horizontal split case is parallel to the shaft centerline.

A single volute pump, Figure 1, has one channel that increases in cross section thereby converting the kinetic energy into pressure.At the best efficiency point (BEP) the pressures on opposite sides of the impeller are essentially equal. However, at partial flows the pressures are not equal and could be sufficiently large enough to cause excessive deflection of the shaft, especially in high head pumps.

To minimize this deflection a double volute pump is used, Figure 2. A second channel is cast into the pump casing which equalizes the pressures across the impeller better. The double volute provides similar flow channels with outlets 180 degrees apart, which result in a considerable reduction in the radial loads on the shaft.

In a diffuser casing, Figure 3, the vanes are designed to form passages of gradually expanding area to insure a uniform decrease in velocity from inlet to outlet. The multiple passages equalize the pressure at all points about the periphery of the impeller resulting in perfect radial balance.

There are two basic elements of the centrifugal pump: the stationary element and the rotating element. The stationary element consists of the pump case, base plate, stuffing boxes and bearings. The stationary element provides the support and enclosure for the rotating element.

The case provides the suction and discharge nozzles and directs the flow of liquid into and away from the impeller. It converts kinetic energy generated by the impeller into potential energy (pressure). The rotating element consists of a shaft on which is mounted one or more impellers. The rotating element is the means to generate the flow of liquid and the required head of the pump.

Impeller Types

Impellers can be classified as either single or double suction, with either being enclosed, semienclosed or open, Figure 4. The terms single and double suction only designate the

number of inlets contained in the impeller.

A single suction has one inlet, Figure 5, and a double suction has two inlets, Figure 6.

A closed impeller, has a side wall (called shrouds) on both sides of the impeller. A closed impeller will have a wear ring on each side of the inlet to reduce leakage from the discharge back to the suction.

A semiclosed impeller has a shroud on one side of the vanes and the other side is left open.

These types of impellers are not furnished with wear rings and the losses from leakage from the discharge to the suction are higher than a closed impeller.

The open impeller has cast vanes without any shrouds. Its efficiency is low and its use in power plants is limited.

Pump and Head Terminology

The term head is used as a measure of energy in units of feet.

Recall from the incompressible flow module that friction head (hf) is the energy required to

overcome resistance to flow in the pipe, fittings, valves, entrances and exits.

where

hf = head loss (ft)

Le = length of pipe work (ft)

v = velocity of fluid (ft/s)

D = inner diameter of pipe work (ft)

gc = acceleration due to gravity (ft/s²)

Velocity head (hv) is the energy of a fluid as a result of its kinetic energy.

where

hv = Velocity head (ft)

Pressure head (hp) is the pressure of the fluid being pumped.

where

hp = Pressure head (ft)

p = pressure (psi)

𝜌 = fluid density,( lb m/ft³)

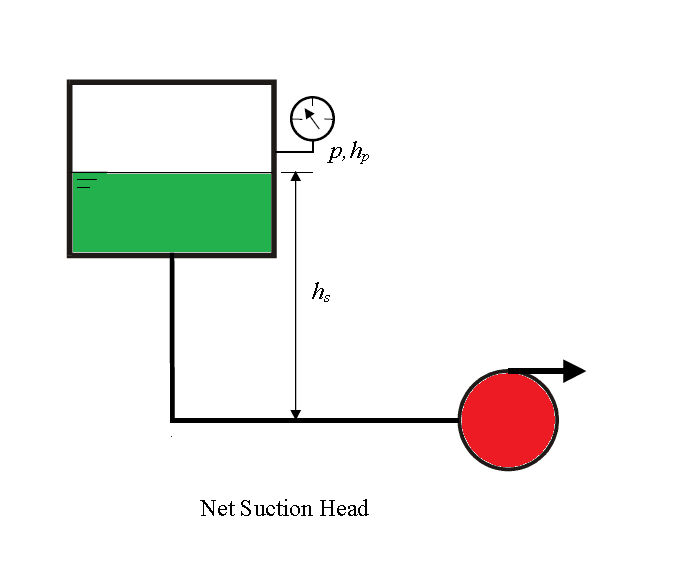

Static suction head (hs) is the vertical distance in feet above the centerline of the pump inlet to

the free level of the fluid source. If the free level of the fluid source is below the pump inlet,

hs will be negative and is referred to as static suction lift.

Static discharge head (hd) is the vertical distance in feet above the pump centerline to the free level of the discharge tank.

Net suction head (Hs) is the total energy of the fluid entering the pump inlet. It includes the

static suction head (hs), plus the pressure head (if any) in the suction tank (hp), plus the suction velocity head (hv), minus the friction head (hf) in the suction piping.

Net discharge head (Hd) is the total energy of the fluid leaving the pump. It includes the static discharge head (hd), plus the discharge velocity head (hv), plus the friction head in the discharge piping (hv), plus the pressure head (if any) in the discharge tank (hp).

where

hvp = fluid’s vapor pressure (ft)

If NPSHA is less than NPSHR, the fluid will cavitate.

Cavitation is the vaporization of the fluid within .the casing or suction line. If the fluid pressure is less than the vapor pressure

NPSHA can be increased by:

· Increasing the height of the supply source or lowering the location of the pump. (Since it is typically difficult to relocate the suction tank without a major

modification, the only option is to raise the level within the tank.)

· Pressurizing the supply tank.

· Reducing the frictional losses between the supply source and the pump – using a larger pipe diameter, reducing the amount of elbows and minor losses, reducing the distance between the supply source and the pump.

· Reducing the fluid flow (velocity) and thereby reducing the friction losses.

· Reducing the pump speed, if possible, and thereby reducing the fluid flow and friction losses.

· Reducing the temperature of the fluid.

· Using booster pumps in front of pumps requiring high NPSHR.

It is important to note that throttling the suction piping increases the friction head term and

thus decreases the NPSHA. Also, evacuating the discharge tank increases the flow rate that

also increases the friction head term.

Pump Specific Speed

The Hydraulic Institute defines specific speed as a correlation of capacity, head and speed at optimum efficiency that classifies pump impellers with respect to their geometric similarity.

Pump specific speed is expressed as follows:

where

GPM = Volumetric flow rate at best efficiency point

pump components

1- Pump Bearings

The bearings in a centrifugal pump must perform the following functions:

· permit the shaft to rotate with very low friction

· hold the rotating element in position both radially and axially thereby eliminating rubbing

· absorb the forces generated by the impeller

· provide long life and reliability

Bearings in a centrifugal pump are classified according to the direction of the forces they absorb. Centrifugal pump bearings may be ball or rolling element antifriction bearings, sleeve type journal bearings, or hydrodynamic thrust bearings. Journal bearings will absorb only radial loads, hydrodynamic thrust bearings will absorb only axial loads, but antifriction bearings will absorb both radial and axial loads.

2- Pump Shaft Seals

All pumps have the problem of sealing the shaft where it extends through the pump casing.

The three ways to accomplish this are:

· packing figure 9

· throttle Bushing with seal injection

· mechanical Seals. figure 10

3- impeller

4- casing

5- shaft

Pump Application

Performance of Centrifugal Pumps

Not all centrifugal pump curves are identical, Figure 11. Some gradually increase from runout to shutoff, some increases steeply over very small flow ranges, some are flatter, and others have humps. Every centrifugal pump has a fixed design geometry so that all the flow areas are optimized to produce a given head and flow with minimal losses. This design point is called the Best Efficiency Point (BEP).

Operation on either side of the best efficiency point will introduce losses that will affect pump performance.

Pump Runout

Pump runout refers to the maximum flow rate at the lowest anticipate system head. Pumps that operate in an oversized system can each their maximum flow rates due to too low of a system head loss. Correctly sized pumps can reach runout due to ruptures in the system that drastically reduce head loss. Runout results in:

· Pump efficiency decreasing – the runout flow is typically much higher that the best efficiency point

· Eventual flow loss (possible cavitation problems) – the runout flow typically has much higher NPSH requirements

· Overheating the motor and/or pump

Methods to prevent runout include:

· System design – choose the correct pump for the system

· Throttle the discharge to prevent high flow rates

· Create some minimum static head that the pump must always discharge against

· Provide alarms if flow rates become excessive

Efficiency Curve

A typical centrifugal pump efficiency curve is shown in Figure 12. This curve represents how well the pump converts the mechanical energy from the driver or shaft into increased pressure energy of the fluid being pumped. Inefficiencies are caused by the fluid being recirculated within the pump casing. Inefficiencies are also caused

by the energy going into the fluid as increased internal energy (temperature) instead

of pressure. This is caused by friction between the fluid and the impeller.

Efficiencies at the BEP can be as high as 90% for many centrifugal pumps. As the

figure illustrates, at noflow

conditions all of the energy is being absorbed by the fluid

as an increase in its temperature and thus the pump efficiency is zero.

Pump efficiency is defined as follows:

Horsepower

The horsepower required to develop the head and flow in a centrifugal pump will vary with the flow rate of the pump. The following equation expresses this relationship:

where

Q = Volumetric flow rate at best efficiency point (GPM)

H = Total dynamic head (ft)

SG = Specific Gravity

EFF = Pump Efficiency

WHP = Water Horsepower

System Resistance Curve

The head required to be generated by any pump is determined by the system resistance curve. The system resistance curve is comprised of three basic components:

· Static Head

· Pressure Head

· Friction Head

Figure 13 illustrates how these components combine to create a system resistance curve.

The pressure and static head are constant at all flow rates but, the friction head increases as flow rate increases. Once the system resistance curve has been generated, pump performance can be selected that provides the flow rate necessary to meet the demands of the system.

Introduction

Pumps can be classified into two categories based on the method by which pumping energy is transmitted to the fluid: kinetic and positive displacement pumps. Most kinetic pumps are centrifugal pumps. Liquid flowing into the suction side or inlet of a centrifugal pump is captured by the impeller and thrown to the outside of the pump casing, or volute. The volute converts the velocity imparted to the fluid by the impeller into pressure.

Pump Types

Centrifugal pumps are divided into:

· Single and multistage volute types with single and double suction impellers.

· Multistage diffuser types with single suction impellers.

These are further divided into:

· Radial or vertical split or

· Axial or horizontal split case types.

Volute type pumps are further divided into:

· Single Volute

· Double volute

All casings of the radial or vertical split have the casing split at right angles to the shaft centerline, whereas, the horizontal split case is parallel to the shaft centerline.

A single volute pump, Figure 1, has one channel that increases in cross section thereby converting the kinetic energy into pressure.At the best efficiency point (BEP) the pressures on opposite sides of the impeller are essentially equal. However, at partial flows the pressures are not equal and could be sufficiently large enough to cause excessive deflection of the shaft, especially in high head pumps.

|

| FIG 1 |

|

| FIG 2 |

|

| FIG 3 |

There are two basic elements of the centrifugal pump: the stationary element and the rotating element. The stationary element consists of the pump case, base plate, stuffing boxes and bearings. The stationary element provides the support and enclosure for the rotating element.

The case provides the suction and discharge nozzles and directs the flow of liquid into and away from the impeller. It converts kinetic energy generated by the impeller into potential energy (pressure). The rotating element consists of a shaft on which is mounted one or more impellers. The rotating element is the means to generate the flow of liquid and the required head of the pump.

Impeller Types

Impellers can be classified as either single or double suction, with either being enclosed, semienclosed or open, Figure 4. The terms single and double suction only designate the

number of inlets contained in the impeller.

|

| FIG 4 |

|

| FIG 5 |

|

| FIG 6 |

A closed impeller, has a side wall (called shrouds) on both sides of the impeller. A closed impeller will have a wear ring on each side of the inlet to reduce leakage from the discharge back to the suction.

A semiclosed impeller has a shroud on one side of the vanes and the other side is left open.

These types of impellers are not furnished with wear rings and the losses from leakage from the discharge to the suction are higher than a closed impeller.

The open impeller has cast vanes without any shrouds. Its efficiency is low and its use in power plants is limited.

Pump and Head Terminology

The term head is used as a measure of energy in units of feet.

Recall from the incompressible flow module that friction head (hf) is the energy required to

overcome resistance to flow in the pipe, fittings, valves, entrances and exits.

where

hf = head loss (ft)

Le = length of pipe work (ft)

v = velocity of fluid (ft/s)

D = inner diameter of pipe work (ft)

gc = acceleration due to gravity (ft/s²)

Velocity head (hv) is the energy of a fluid as a result of its kinetic energy.

where

hv = Velocity head (ft)

Pressure head (hp) is the pressure of the fluid being pumped.

where

hp = Pressure head (ft)

p = pressure (psi)

𝜌 = fluid density,( lb m/ft³)

Static suction head (hs) is the vertical distance in feet above the centerline of the pump inlet to

the free level of the fluid source. If the free level of the fluid source is below the pump inlet,

hs will be negative and is referred to as static suction lift.

Static discharge head (hd) is the vertical distance in feet above the pump centerline to the free level of the discharge tank.

Net suction head (Hs) is the total energy of the fluid entering the pump inlet. It includes the

static suction head (hs), plus the pressure head (if any) in the suction tank (hp), plus the suction velocity head (hv), minus the friction head (hf) in the suction piping.

Hs = hs + hp - hf

|

| FIG 7 |

Net discharge head (Hd) is the total energy of the fluid leaving the pump. It includes the static discharge head (hd), plus the discharge velocity head (hv), plus the friction head in the discharge piping (hv), plus the pressure head (if any) in the discharge tank (hp).

|

| FIG 8 |

Total dynamic head (H) is the net discharge head minus the net suction head. Is the total amount of energy added to the fluid by the pump.

Liquid is not sucked into a pump. A positive head (normally atmospheric pressure) must push the liquid into the impeller. Net positive suction head required (NPSHR) is the minimum fluid energy required at the inlet to the pump for satisfactory operation. NPSHR is specified by the pump manufacturer. It accounts for any additional frictional losses from the pump suction flange and entrance the impellers. It is rarely, if ever, determined after installation.

Net positive suction head available (NPSHA) is the fluid energy at the inlet to the pump above

the fluid’s vapor pressure.

Net positive suction head available (NPSHA) is the fluid energy at the inlet to the pump above

the fluid’s vapor pressure.

hvp = fluid’s vapor pressure (ft)

If NPSHA is less than NPSHR, the fluid will cavitate.

Cavitation is the vaporization of the fluid within .the casing or suction line. If the fluid pressure is less than the vapor pressure

NPSHA can be increased by:

· Increasing the height of the supply source or lowering the location of the pump. (Since it is typically difficult to relocate the suction tank without a major

modification, the only option is to raise the level within the tank.)

· Pressurizing the supply tank.

· Reducing the frictional losses between the supply source and the pump – using a larger pipe diameter, reducing the amount of elbows and minor losses, reducing the distance between the supply source and the pump.

· Reducing the fluid flow (velocity) and thereby reducing the friction losses.

· Reducing the pump speed, if possible, and thereby reducing the fluid flow and friction losses.

· Reducing the temperature of the fluid.

· Using booster pumps in front of pumps requiring high NPSHR.

It is important to note that throttling the suction piping increases the friction head term and

thus decreases the NPSHA. Also, evacuating the discharge tank increases the flow rate that

also increases the friction head term.

Pump Specific Speed

The Hydraulic Institute defines specific speed as a correlation of capacity, head and speed at optimum efficiency that classifies pump impellers with respect to their geometric similarity.

Pump specific speed is expressed as follows:

where

GPM = Volumetric flow rate at best efficiency point

pump components

1- Pump Bearings

The bearings in a centrifugal pump must perform the following functions:

· permit the shaft to rotate with very low friction

· hold the rotating element in position both radially and axially thereby eliminating rubbing

· absorb the forces generated by the impeller

· provide long life and reliability

Bearings in a centrifugal pump are classified according to the direction of the forces they absorb. Centrifugal pump bearings may be ball or rolling element antifriction bearings, sleeve type journal bearings, or hydrodynamic thrust bearings. Journal bearings will absorb only radial loads, hydrodynamic thrust bearings will absorb only axial loads, but antifriction bearings will absorb both radial and axial loads.

2- Pump Shaft Seals

All pumps have the problem of sealing the shaft where it extends through the pump casing.

The three ways to accomplish this are:

· packing figure 9

· throttle Bushing with seal injection

· mechanical Seals. figure 10

|

| FIG 9 |

|

| FIG 10 |

4- casing

5- shaft

Pump Application

Performance of Centrifugal Pumps

Not all centrifugal pump curves are identical, Figure 11. Some gradually increase from runout to shutoff, some increases steeply over very small flow ranges, some are flatter, and others have humps. Every centrifugal pump has a fixed design geometry so that all the flow areas are optimized to produce a given head and flow with minimal losses. This design point is called the Best Efficiency Point (BEP).

Operation on either side of the best efficiency point will introduce losses that will affect pump performance.

|

| FIG 11 |

Pump runout refers to the maximum flow rate at the lowest anticipate system head. Pumps that operate in an oversized system can each their maximum flow rates due to too low of a system head loss. Correctly sized pumps can reach runout due to ruptures in the system that drastically reduce head loss. Runout results in:

· Pump efficiency decreasing – the runout flow is typically much higher that the best efficiency point

· Eventual flow loss (possible cavitation problems) – the runout flow typically has much higher NPSH requirements

· Overheating the motor and/or pump

Methods to prevent runout include:

· System design – choose the correct pump for the system

· Throttle the discharge to prevent high flow rates

· Create some minimum static head that the pump must always discharge against

· Provide alarms if flow rates become excessive

Efficiency Curve

A typical centrifugal pump efficiency curve is shown in Figure 12. This curve represents how well the pump converts the mechanical energy from the driver or shaft into increased pressure energy of the fluid being pumped. Inefficiencies are caused by the fluid being recirculated within the pump casing. Inefficiencies are also caused

by the energy going into the fluid as increased internal energy (temperature) instead

of pressure. This is caused by friction between the fluid and the impeller.

Efficiencies at the BEP can be as high as 90% for many centrifugal pumps. As the

figure illustrates, at noflow

conditions all of the energy is being absorbed by the fluid

as an increase in its temperature and thus the pump efficiency is zero.

Pump efficiency is defined as follows:

|

| FIG 12 |

Horsepower

The horsepower required to develop the head and flow in a centrifugal pump will vary with the flow rate of the pump. The following equation expresses this relationship:

where

Q = Volumetric flow rate at best efficiency point (GPM)

H = Total dynamic head (ft)

SG = Specific Gravity

EFF = Pump Efficiency

WHP = Water Horsepower

System Resistance Curve

The head required to be generated by any pump is determined by the system resistance curve. The system resistance curve is comprised of three basic components:

· Static Head

· Pressure Head

· Friction Head

Figure 13 illustrates how these components combine to create a system resistance curve.

The pressure and static head are constant at all flow rates but, the friction head increases as flow rate increases. Once the system resistance curve has been generated, pump performance can be selected that provides the flow rate necessary to meet the demands of the system.

|

| FIG 13 |

It is important to remember that the pump will always operate at the intersection of the pump performance curve and the system resistance curve, Figure 14.

|

| FIG 14 |

When developing the system resistance curve, all of the systems operating conditions must be considered. For example, if a control valve is included in the system, the system curve must be evaluated with the control valve fully open. If this is not considered, the system resistance curve could intersect the pump performance curve near or beyond pump runout. The pump could experience cavitation, due to insufficient NPSH, or the motor could be overloaded. The minimum flow of the system should also be evaluated. Every pump has a minimum flow at which it can operate. As a general rule, the minimum flow for a centrifugal pump is 25% of the flow at BEP. However, some pumps can require more or less than 25%. The pump manufacturer should be consulted for the exact

requirement. Cavitation damage could occur if a pump is operated at less than its minimum flow requirement. This type of cavitation damage is due to the internal recirculation that occurs when impellers are operated at very low flows. This occurs because the pump was designed to operate at the best efficiency point and operating at flows less than the BEP cause the flow to recirculate in the impeller region instead of flowing completely through the impeller.

BEP - Best Efficiency Point - Pump

A practical pump will never be able to convert all its kinetic energy to pressure energy. Parts of the energy will always be internal or external lost.

1- hydraulic loss - due to disk friction in the impeller, rapid change in flow directions and velocity changes throughout the pump

2- volumetric loss - due to internal re-circulation caused by wear in rings and bushes

External Losses

mechanical loss - due to friction in seals and bearings

The maximum efficiency for a pump is normally in its "design point" - also called

BEP - or the "Best Efficiency Point"

For pumps operating in all other positions - the efficiency will be less than in BEP.

|

Wow, you know a lot about centrifugal pump. thanks for sharing. I'm appreciated!

ReplyDeleteKTronics controllers are specially designed for water level control and level indication purposes. It is developed with fit for all motors simple operations.

ReplyDeleteKTronics controllers are specially designed for water level control and level indication purposes. It is developed with fit for all motors simple operations.

ReplyDelete

ReplyDeleteGreat Post! Thanks for sharing such beautiful information with us. Please keep sharing.

Please visit reticulation supplies rockingham

Keep sharing these informative blogs, I really appreciate the efforts made by the blogger. Vacuum Insulated Glass

ReplyDelete